Real-time Hybrid Simulations of a Large-scale Steel Structure with Nonlinear Viscous Dampers Subjected to the Maximum Considered Earthquake Hazard Level

July 18, 2013

July 18, 2013 between 9 am and 4 pm EST

The NEESR project entitled NEESR-CR: Performance-Based Design for Cost-Effective Seismic Hazard Mitigation in New Buildings Using Supplemental Passive Damper Systems (PI: Richard Sause) is currently conducting a series of large-scale real-time hybrid simulations (RTHS) on a 3-story steel frame building at the Real-time Multi-directional (RTMD) Earthquake Simulation Facility, the Lehigh NEES Equipment Site. The goal for this NEESR project is to develop a validated, probabilistic, performance-based seismic design procedure for buildings with passive damping systems.

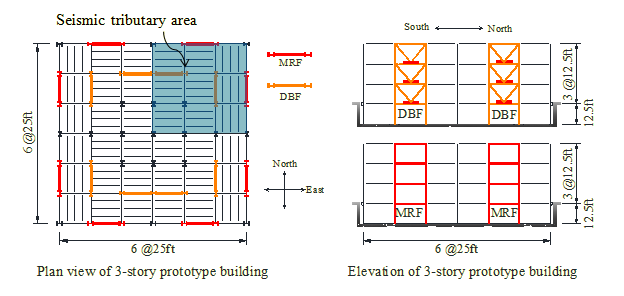

The RTHS will be used to experimentally validate the performance-based seismic design of the 3-story building constructed of structural steel and equipped with nonlinear rate-dependent viscous dampers. The prototype building for the study is located in Pomona, California and the steel structure is designed for 75% and 60% of the code design base shear, but not the code-required drift control. A performance based design procedure to control drift and thereby avoid damage to the building under the design earthquake.

In the RTHS, the complete building is represented as an experimental substructure and an analytical substructure. The experimental substructure consists of a large-scale 3-story steel moment resisting frame (MRF) and a braced frame with nonlinear viscous dampers and diagonal braces supporting the dampers, and the analytical substructure is comprised of the remaining parts of building, including gravity load frames, seismic mass, and the inherent damping of the building. This experimental substructure differs from previous experimental substructures used in this project, because it includes the MRFs of the building, and is the largest ever used in RTHS. The analytical substructure has a total of 10 DOFs, which provides a model of the gravity load system. In addition, geometric nonlinearities are included to account for the P-delta effects of the gravity load system of the building.

The RTHS data will be used to observe and understand the interactions of the viscous dampers with the braces, beams, and columns of the experimental substructure as well as the interactions between the steel frame with the dampers and the rest of the building. The project team has developed detailed analytical (numerical simulation) models of the prototype building with nonlinear viscous dampers, and the RTHS data will be used to validate the models.

The current series of RTHS will utilize ground motions scaled to the maximum considered earthquake (MCE) level, associated with a return period of about 2500 years. Robust actuator control algorithms will be used in conjunction with a complex MDOF nonlinear analytical substructure and an unconditionally stable explicit integration algorithm. The control algorithms, nonlinear analysis tool, and integration algorithm have been developed and implemented by the Lehigh Equipment Site as tools to support large-scale RTHS. The RTHS will be the first of their kind, involving large-scale real time simulations of a multi-story steel frame subjected to MCE-level ground motions.

The RTHS will take place on July 18, 2013 between 9 am and 4 pm EST. The RTHS test matrix includes conducting a series of simulations using an ensemble of earthquake records at the maximum considered earthquake (MCE) level. The RTHS can be viewed by telepresence, where webcams and the Real-Time Data Viewer can be used to view video, data and animation of the response of the building acquired from the RTHS. The RTHS can be viewed by telepresence, where webcams and the Real-Time Data Viewer can be used to view video, data and animation of the response of the building acquired from the RTHS. Results (including video) from completed tests will also be archived and available here and through the Project Warehouse on NEES.org. Also, follow us on Facebook to get up to the minute simulation updates from our research team.

The project is a collaborative effort that includes California State University, Northridge; California State Polytechnic University, Pomoma; Lehigh University; The Pennsylvania State University, Erie; and Tokyo Institute of Technology. Industry partners include Corry Rubber Company, Taylor Devices, Miyamoto International, Inc. and Simpson Gumpertz & Heger.

More information about the above NEESR project can be found at http://www.rtmd.lehigh.edu/projects/pbd-for-seismic-hazard-mitigation. Data can be accessed at NEEShub for the completed projects, in addition to data for completed phases of the above project.

Run Real-time Data Viewer (RDV) version 2.2.3

Run Real-time Data Viewer (RDV) version 2.2.3